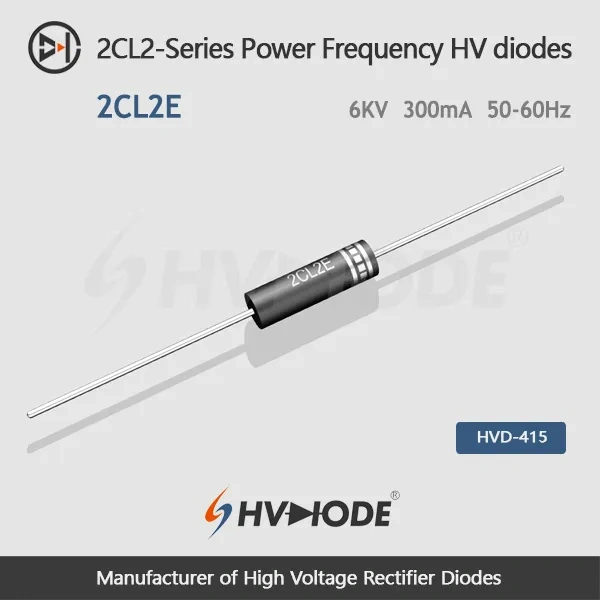

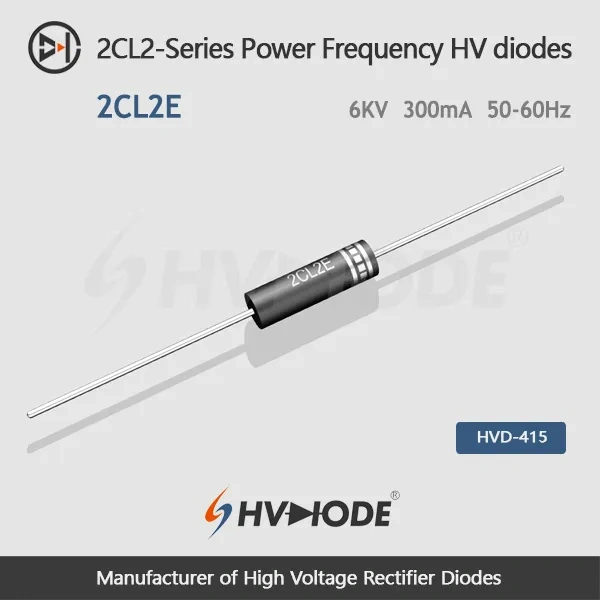

| 2CL2E Power Frequency High Voltage Diode Data Sheet | ||||

| Parameter | Symbol | Unit | Test Conditions | Value |

| Repetitive Peak Backward Voltage | Vrrm | KV | Ta=25℃ Ir=2.0μA | 6 |

| Peak Working Backward Voltage | Vrwm | KV | Ta=25℃ Ir=2.0μA | 6 |

| Average Forward Current | If(AV) | mA | 50Hz Half-sine Wave , Resistance load @Tbreak=50℃ | 300 |

| Backward Recovery Time | Trr | nS | -- | |

| Surge Forward Current | Ifsm | A | 0.01S @ Half-Sine wave 50Hz | 20 |

| Operating Ambient Temperature | Ta | ℃ | -55~+150 | |

| Storage Temperature | Tstg | ℃ | -55~+125 | |

| Forward Peak Voltage | Vfm | V | ≥7.0 | |

| Backward Peak Current | Irrm1 | μA | @ Ta=25℃ VRM=VRRM | 2.0 |

| Irrm2 | μA | @ Ta=100℃ VRM=VRRM | 20.0 | |

| Absolute Maximum Ratings & Electrical Characteristics | ||||

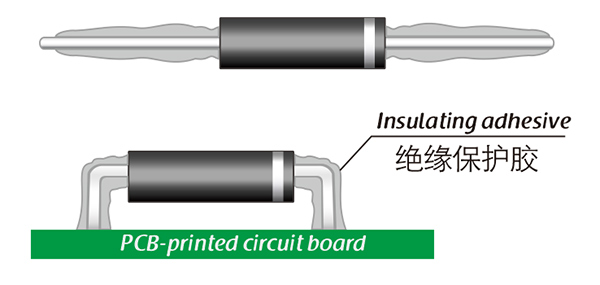

Here, suitable insulation adhesive materials can be selected based on the different usage situations of engineers.